स्वागत छ! म एलेन हुँ, र चीनमा विशेषज्ञता भएको कारखाना सञ्चालन गर्ने वर्षौंको अनुभवको साथ डिस्पोजेबल चिकित्सा उपभोग्य वस्तुहरू, मैले प्रत्यक्ष रूपमा महत्वपूर्ण भूमिका उचित देखेको छु श्वसन सुरक्षा विभिन्न सेटिङहरूमा खेल्छ। अस्पतालदेखि औद्योगिक साइटहरू, विरुद्ध सुरक्षा वायुजनित कणहरू, ग्यास, र भाप सर्वोपरि छ। यो लेख संसारमा गहिरो डुब्छ डिस्पोजेबल रेस्पिरेटरहरूजस्तै विश्वसनीय ब्रान्डहरूमा अन्तर्दृष्टि सहित ३M। हामी अन्वेषण गर्नेछौं रेस्पिरेटर को प्रकार, अधिकारको महत्व फिल्टर वा कारतूस, र कसरी सूचित छनौट गर्ने व्यावसायिक सुरक्षा र स्वास्थ्य। यदि तपाईं मार्क थम्पसन जस्तै हुनुहुन्छ, एक खरीद प्रबन्धक विश्वसनीय, अनुरूप, र लागत-प्रभावी समाधानहरू खोज्दै हुनुहुन्छ, यो गाइडले तपाईंलाई आफ्नो टोलीहरूलाई प्रभावकारी रूपमा सुरक्षित गर्न आवश्यक स्पष्टता प्रदान गर्नेछ। यी यन्त्रहरू बुझ्दै, सरलबाट N95 रेस्पिरेटर थप जटिल प्रणालीहरूमा, सुरक्षा र अनुपालन सुनिश्चित गर्न कुञ्जी हो।

1. आजको संसारमा श्वासप्रश्वास सुरक्षा किन यति महत्वपूर्ण छ?

मेरो कामको लाइनमा, बाट सबै उत्पादन गर्दै मेडिकल सर्जिकल फेस मास्क उन्नत गर्न श्वासप्रश्वास हेरचाह वस्तुहरू, वरपर कुराकानी श्वसन सुरक्षा कहिल्यै बढी सान्दर्भिक भएको छैन। हामीले सास फेर्ने हावाले, दुर्भाग्यवश, अदृश्य खतराहरू बोक्न सक्छ। यी स्वास्थ्य सेवा सेटिङहरूमा जैविक एजेन्टहरूदेखि धुलोसम्म हुन सक्छन्, धुवाँर रासायनिक भाप औद्योगिक वातावरणमा। मार्क थम्पसन जस्ता पेशेवरहरूको लागि, सुनिश्चित गर्दै सुरक्षा र स्वास्थ्य कर्मचारीको संख्या केवल नियामक आवश्यकता मात्र होइन; यो एक नैतिक अनिवार्य छ। एक बलियो श्वसन सुरक्षा कार्यक्रम, जसमा a को सही प्रयोग समावेश छ श्वासप्रश्वास यन्त्र, को आधारशिला हो व्यावसायिक सुरक्षा र स्वास्थ्य.

अपर्याप्त को परिणाम श्वसन सुरक्षा गम्भीर हुन सक्छ, जसले तीव्र रोग वा पुरानो अवस्थाहरू निम्त्याउँछ। संक्रामकको सम्पर्कमा रहेका स्वास्थ्यकर्मीहरूको बारेमा सोच्नुहोस् एरोसोल थोपा वा निर्माण कार्यकर्ताहरू ठीक सास लिँदै कण कुरा। प्रत्येक खतरा विशेष प्रकारको माग गर्दछ श्वासप्रश्वास यन्त्र को रक्षा गर्न मद्दत गर्नुहोस् द लगाउने। लक्ष्य सधैं हुन्छ एक्सपोजर कम गर्नुहोस् निम्न हानिकारक पदार्थहरु को लागी स्वीकार्य एक्सपोजर सीमा (PEL) वा अन्य एक्सपोजर सीमा। यहाँ बुझ्ने फरक छ रेस्पिरेटर को प्रकार र तिनीहरूको आवेदन एकदम महत्त्वपूर्ण हुन्छ। यो लगाउने बारेमा मात्र होइन श्वासप्रश्वास यन्त्र; यो लगाउने बारेमा छ सही श्वासप्रश्वास यन्त्र, राम्रोसँग फिट र मर्मत गरिएको।

2. डिस्पोजेबल रेस्पिरेटर के हो र यसले कसरी काम गर्छ?

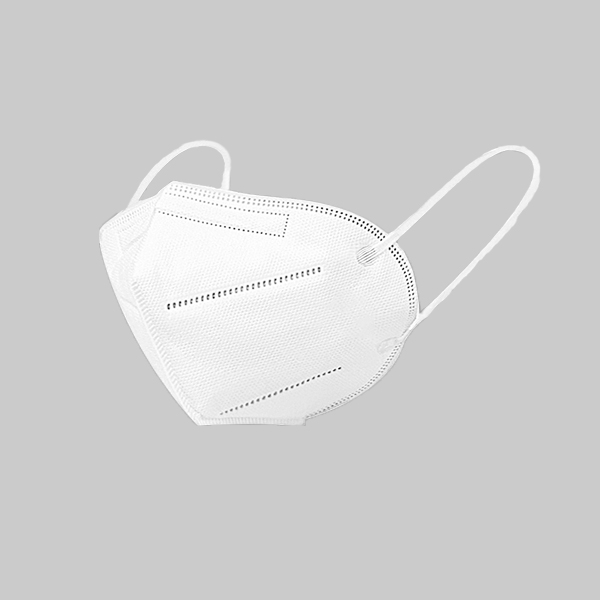

A डिस्पोजेबल श्वास यन्त्र, अक्सर a को रूपमा उल्लेख गरिएको छ फिल्टरिङ फेसपीस रेस्पिरेटर (FFR), एक प्रकार हो व्यक्तिगत सुरक्षा उपकरण (पीपीई) गर्न डिजाइन गरिएको लगाउनेलाई रक्षा गर्नुहोस् खतरनाक सास फेर्नबाट वायुजनित कणहरूधुलो, धुवाँ र धुवाँ सहित। विपरीत पुन: प्रयोज्य श्वसन यन्त्रहरू जुन प्रतिस्थापन योग्य छ कारतूस र फिल्टर, क डिस्पोजेबल श्वास यन्त्र को लागि सामान्यतया डिजाइन गरिएको छ एकल प्रयोग वा सीमित प्रयोग र त्यसपछि छ प्रयोग पछि खारेज। सम्पूर्ण अनुहार यी मध्ये श्वासप्रश्वासकहरू हुन सक्छन् को रूपमा कार्य गर्दछ फिल्टर। धेरै मानिसहरू परिचित छन् N95 रेस्पिरेटर, जुन एक सामान्य प्रकार हो डिस्पोजेबल श्वास यन्त्र.

यी श्वासप्रश्वासकहरू a सिर्जना गरेर काम गर्नुहोस् कडा छाप वरपर नाक र मुख (वा कहिलेकाहीँ पूरा अनुहार, यद्यपि डिस्पोजेबलहरूको लागि कम सामान्य)। को रूपमा लगाउने सास लिन्छ, हावा मार्फत तानिन्छ फिल्टर मा एकीकृत सामग्री श्वासप्रश्वास यन्त्रका किनारहरू र शरीर, जसले जालमा पार्छ कण प्रदूषक। यो महत्त्वपूर्ण छ कि श्वासप्रश्वास यन्त्र राम्रोसँग फिट हुन्छ; कुनै पनि अंतरालले दूषित हावालाई बाइपास गर्न अनुमति दिन सक्छ फिल्टर, सम्झौता संरक्षण। यही कारणले फिट परीक्षण प्रायः आवश्यक हुन्छ पेशागत सेटिङहरू। केही डिस्पोजेबल रेस्पिरेटरहरू पनि एक सुविधा सास फेर्न वाल्व, जसले सास फेर्न सजिलो बनाउन सक्छ र भित्र तातो निर्माण कम गर्न सक्छ अनुहार, तर स्रोत नियन्त्रण (प्रदूषकहरूलाई सास फेर्नबाट जोगाउने) लाई पनि आवश्यक भएमा यी उपयुक्त छैनन्।

3. ल्यान्डस्केप अन्वेषण: विभिन्न प्रकारका रेस्पिरेटरहरू के हुन्?

जब हामी कुरा गर्छौं श्वासप्रश्वासकहरू, यो एक व्यापक वर्ग हो। एक निर्माता को रूप मा, हामी विभिन्न को लागी मांग देख्छौं रेस्पिरेटर को प्रकार, प्रत्येक फरक वातावरण र स्तरहरूको लागि उपयुक्त खतरा। सबैभन्दा आधारभूत भिन्नता हावा शुद्धीकरण बीचको हो श्वासप्रश्वासकहरू (एपीआर) र वातावरण आपूर्ति श्वासप्रश्वासकहरू. डिस्पोजेबल रेस्पिरेटरहरू, जस्तै N95, विशेष गरी APR अन्तर्गत पर्दछ फेसपीस रेस्पिरेटरहरू फिल्टर गर्दै। यी रेस्पिरेटरहरू डिजाइन गरिएका छन् परिवेशको हावाबाट विशिष्ट प्रदूषकहरू हटाउन। त्यसपछि त्यहाँ छन् पुन: प्रयोज्य श्वसन यन्त्रहरू, जुन हुन सक्छ आधा मास्क रेस्पिरेटरहरू (कभर गर्दै मुख र नाक) वा फुल-फेस रेस्पिरेटरहरू (आँखा सुरक्षा पनि प्रदान गर्दै)। यी बदल्न योग्य प्रयोग कारतूस र फिल्टर विशेष ग्याँस, वाष्प, वा कणहरू लक्षित गर्न।

यी बाहेक, तपाईंसँग संचालित वायु-शुद्धि गर्ने रेस्पिरेटरहरू छन् (PAPR), जसले हावा पास गर्न ब्लोअर प्रयोग गर्दछ फिल्टर र मा अनुहार, सास फेर्न सजिलो बनाउन। अक्सिजनको कमी वा प्रदूषकहरूको अत्यधिक उच्च सांद्रता भएको वातावरणको लागि, ए आत्म-निहित श्वास उपकरण (SCBA) वा आपूर्ति-हावा श्वासप्रश्वास यन्त्र आवश्यक छ, किनकि यी सफा प्रदान गर्दछ लगाउनेलाई हावा स्वतन्त्र स्रोतबाट। बुझ्दै विभिन्न प्रकारका श्वसन यन्त्रहरू मा पहिलो चरण हो सही श्वासप्रश्वास यन्त्र छनौट गर्दै कामको लागि। प्रत्येक फिल्टर को प्रकार र श्वासप्रश्वास यन्त्र एउटा छ तोकिएको संरक्षण कारक (APF), राम्रोसँग फिट र प्रयोग गर्दा यसले प्रस्ताव गर्न सक्ने सुरक्षाको स्तरलाई संकेत गर्दछ।

4. संरक्षणको मूल: रेस्पिरेटर फिल्टर र कारतूसले कसरी काम गर्छ?

द फिल्टर वा कारतूस कुनै पनि वायु शुद्धिकरणको मुटु हो श्वासप्रश्वास यन्त्र। को लागी डिस्पोजेबल रेस्पिरेटरहरूजस्तै एक N95 रेस्पिरेटर, द फिल्टर मिडियाको अभिन्न अंग हो अनुहार आफैं, पासो बनाउन डिजाइन गरिएको कण कुरा। यी कण फिल्टरहरू क्याप्चर गर्न जडत्वीय प्रभाव, अवरोध, प्रसार, र इलेक्ट्रोस्टेटिक आकर्षण सहित संयन्त्रहरूको संयोजन मार्फत काम गर्नुहोस्। वायुजनित कणहरू जसरी हावा पास हुन्छ। यिनीहरूको दक्षता फिल्टरहरू के जस्तै मूल्याङ्कन दिन्छ N95 (फिल्टर मा कम्तिमा 95वायुजनित कणहरूको%, होइन तेल प्रतिरोधी)।

को लागी पुन: प्रयोज्य श्वसन यन्त्रहरू, कारतूस र फिल्टर अलग-अलग कम्पोनेन्टहरू हुन् जुन संलग्न छन् अनुहार. श्वसन कारतूस सामान्यतया ग्यास र वाष्पहरू विरुद्ध सुरक्षाको लागि प्रयोग गरिन्छ, जस्तै जैविक वाष्पहरू, एसिड ग्याँसहरू (जस्तै सल्फर डाइअक्साइड वा क्लोरीन डाइअक्साइड), वा अमोनिया। तिनीहरूमा sorbent सामाग्री (सक्रिय कार्बन जस्तै) समावेश गर्दछ जसले सोख्छ वा विशिष्ट रसायनसँग प्रतिक्रिया गर्दछ। दूषित. कण फिल्टरहरू को लागी पुन: प्रयोज्य श्वसन यन्त्रहरू एक्लै वा संयोजनमा प्रयोग गर्न सकिन्छ ग्यास/भाप कारतूस (प्रयोग गर्दै संयोजन कारतूस)। यो सही छनोट गर्न महत्त्वपूर्ण छ फिल्टर को प्रकार वा कारतूस विशिष्ट को लागी खतरा वर्तमान र पालन गर्न a तालिका परिवर्तन गर्नुहोस्, किनकि तिनीहरूसँग सीमित सेवा जीवन छ। एक पटक संतृप्त वा भरिएको, द फिल्टर वा कारतूस अब प्रदान गर्दैन पर्याप्त सुरक्षा, र यो बन्न सक्छ सास फेर्न गाह्रो.

5. वर्णमाला सूपको डिकोडिङ: रेस्पिरेटरमा NIOSH रेटिङहरू (N95, P100, आदि) को अर्थ के हो?

जब तपाइँ जस्तै रेटिंग देख्नुहुन्छ N95, R95, वा P100 a मा श्वासप्रश्वास यन्त्र, यी बाट वर्गीकरण हो व्यावसायिक सुरक्षा को लागी राष्ट्रिय संस्थान र स्वास्थ्य (NIOSH), एक अमेरिकी संघीय एजेन्सी अनुसन्धान सञ्चालन गर्न र काम-सम्बन्धित चोट र रोगको रोकथामको लागि सिफारिसहरू बनाउन जिम्मेवार छ। यी मूल्याङ्कनहरू विशेष रूपमा लागू हुन्छन् फिल्टर को दक्षता कण श्वासप्रश्वासकहरू। पत्रले संकेत गर्दछ फिल्टरको तेल प्रतिरोध:

- N: होइन तेल प्रतिरोधी। यी फिल्टरहरू लागि उपयुक्त छन् कण समावेश नहुने खतराहरू तेल आधारित कणहरू.

- R: केही हदसम्म तेल प्रतिरोधी। यी फिल्टरहरू तेल एरोसोलहरू विरुद्ध प्रयोग गर्न सकिन्छ तर सामान्यतया 8 घण्टाको प्रयोगमा सीमित हुन्छ जब तेल उपस्थित हुन्छ।

- P: दृढतापूर्वक तेल प्रतिरोधी (वा तेल-प्रमाण)। यी फिल्टरहरू जोखिमहरु को लागी प्रयोग गर्न सकिन्छ तेल आधारित कणहरू र सामान्यतया लामो सेवा जीवन हुन्छ, यद्यपि निर्माताको सिफारिसहरू (3M सिफारिस गर्नुभयो विशेष दिशानिर्देशहरू जाँच गर्दै) सधैं पालना गर्नुपर्छ।

अक्षर पछिको संख्या (जस्तै, ९५, 99, वा 100) को न्यूनतम प्रतिशत संकेत गर्दछ वायुजनित कणहरू द फिल्टर द्वारा परीक्षण गर्दा हटाउन प्रमाणित छ NIOSH.

- ९५: मा फिल्टर गर्नुहोस् कम्तिमा 95वायुजनित कणहरूको %।

- ९९: कम्तिमा 99% वायुजनित कणहरू फिल्टर गर्दछ।

- 100: मा फिल्टर गर्नुहोस् कम्तिमा 99.97वायुजनित कणहरूको % (प्रायः HEPA-स्तर निस्पंदन भनिन्छ)। तर, ए P100 फिल्टर तेल-प्रूफ छ र कम्तिमा 99.97% कणहरू फिल्टर गर्दछ।

यो नोट गर्न महत्त्वपूर्ण छ कि यी मूल्याङ्कनहरूका लागि हो कण निस्पंदन मात्र र ग्यास वा वाष्पहरू विरुद्ध सुरक्षामा लागू हुँदैन, जसलाई विशिष्ट आवश्यक पर्दछ कारतूस। सबै NIOSH-अनुमोदित रेस्पिरेटरहरू निस्पंदन दक्षता र सास फेर्न प्रतिरोध सहित कडा सरकारी प्रदर्शन मापदण्डहरू पूरा गर्नुहोस्। सुनिश्चित गर्दै आफ्नो श्वासप्रश्वास यन्त्र छ राष्ट्रिय संस्थान द्वारा अनुमोदित को लागी व्यावसायिक सुरक्षा र स्वास्थ्य विश्वसनीय लागि महत्त्वपूर्ण छ श्वसन सुरक्षा.

6. सही कल गर्दै: तपाइँ कसरी एक विशेष खतराको लागि उपयुक्त श्वासप्रश्वास यन्त्र चयन गर्नुहुन्छ?

सही श्वसन यन्त्र छनोट गर्दै प्रत्यक्ष प्रभाव पार्ने महत्वपूर्ण निर्णय हो सुरक्षा र स्वास्थ्य। को एक विस्तृत दायरा आपूर्ति गर्ने व्यक्तिको रूपमा डिस्पोजेबल चिकित्सा उपभोग्य वस्तुहरू, म सधैं मार्क जस्ता ग्राहकहरूलाई यो छनोट प्रक्रिया व्यवस्थित हुनुपर्छ भन्ने कुरामा जोड दिन्छु। पहिले, पहिचान गर्नुहोस् खतरा। के यो ए कण (धुलो, धुवाँ, धुवाँ), क ग्यास, क भाप, वा संयोजन? को प्रकृति कस्तो छ दूषित र यसको एकाग्रता? तपाईंले सेफ्टी डाटा शीट (SDS) मा परामर्श लिनु पर्छ र सम्भावित रूपमा एक्सपोजर स्तरहरू बुझ्नको लागि हवा अनुगमन सञ्चालन गर्न आवश्यक छ। व्यावसायिक जोखिम सीमा (OELs) जस्तै PEL।

एक पटक द खतरा र यसको एकाग्रता ज्ञात छ, तपाईं आवश्यक निर्धारण गर्न सक्नुहुन्छ असाइन गरिएको सुरक्षा कारक (APF)। द एपीएफ संख्या छ NIOSH नियुक्ति गर्दछ श्वासप्रश्वासकहरू को स्तर संकेत गर्दै श्वसन सुरक्षा कि एक राम्रो काम श्वासप्रश्वास यन्त्र ए लाई प्रदान गर्ने अपेक्षा गरिएको छ लगाउने जब यो सही रूपमा फिट र प्रयोग गरिन्छ। उदाहरणका लागि, ए आधा मास्क श्वसन यन्त्र हुन सक्छ एपीएफ 10 को, जबकि a पूर्ण अनुहार श्वास यन्त्र हुन सक्छ एपीएफ 50 को। तपाइँ त्यसपछि एक चयन गर्नुहोस् श्वासप्रश्वास यन्त्र (र यसको सम्बन्धित फिल्टर वा कारतूस) जसमा एउटा छ एपीएफ गणना गरिएको आवश्यक सुरक्षा स्तर भन्दा बढी वा बराबर र विशिष्टको लागि उपयुक्त छ प्रदूषक(हरू)। उदाहरण को लागी, को लागी जैविक वाष्पहरू, तपाईलाई चाहिन्छ कारतूस विशेष गरी तिनीहरूको लागि डिजाइन गरिएको। को लागी कण खतराहरू, एक N95 रेस्पिरेटर वा उच्च (जस्तै P100) को आधारमा उपयुक्त हुन सक्छ दूषित र तेल छ कि छैन। सधैं सुनिश्चित गर्नुहोस् श्वासप्रश्वास यन्त्र सक्छ वरिपरि कडा छाप बनाउनुहोस् द मुख र नाक (वा पूरा अनुहार)।

7. गुणस्तरमा फोकस गर्नुहोस्: के 3M डिस्पोजेबल रेस्पिरेटरहरू उद्योगमा बेन्चमार्क हुन्?

को दायरामा श्वसन सुरक्षा, द ३M ब्रान्ड निस्सन्देह विश्वव्यापी रूपमा सबैभन्दा मान्यता प्राप्त नाम मध्ये एक हो, र राम्रो कारणको लागि। 3M डिस्पोजेबल रेस्पिरेटरहरू, जस्तै तिनीहरूको व्यापक प्रयोग N95 रेस्पिरेटर मोडेलहरू, गुणस्तर, विश्वसनीयता, र नवीनताको लागि बलियो प्रतिष्ठा स्थापित गरेका छन्। आफैं एक निर्माताको रूपमा, म उच्च गुणस्तरको उत्पादनमा संलग्न कठोर प्रक्रियाहरू बुझ्छु सुरक्षा उपकरण. ३M अनुसन्धान र विकासमा ठूलो लगानी गर्दछ, र तिनीहरूका उत्पादनहरू लगातार प्रदर्शन र कडा मापदण्डहरूको पालनाका लागि चिनिन्छन्। NIOSH। तिनीहरूको फेसपीस रेस्पिरेटरहरू फिल्टर गर्दै प्रदान गर्न ईन्जिनियर गरिएको छ सहज र प्रभावकारी अनुहारको आकार र आकारहरूको विस्तृत श्रृंखलाको लागि फिट, जुन आवश्यक प्राप्त गर्नको लागि महत्त्वपूर्ण छ कडा छाप.

जबकि धेरै उत्कृष्ट निर्माताहरूले उत्पादन गर्छन् रेस्पिरेटरहरू उपलब्ध छन्, ३M यसको लामो इतिहास, व्यापक उत्पादन परीक्षण, र शैक्षिक स्रोतहरूको कारणले प्रायः बेन्चमार्कको रूपमा कार्य गर्दछ। तिनीहरूले एक विस्तृत सरणी प्रस्ताव श्वासप्रश्वासकहरू, फिल्टरहरू, र कारतूस विभिन्न को लागी पेशागत खतराहरू, साधारणबाट कण जटिल रासायनिक एक्सपोजरमा धूलो समावेश जैविक वाष्पहरू वा एसिड ग्याँसहरू। मार्क जस्ता खरीद प्रबन्धकहरूको लागि, छनौट गर्दै 3M रेस्पिरेटर प्रायः भनेको अनुपालनको सन्दर्भमा आश्वासनको स्तर हो लगाउने स्वीकृति। जे होस्, यो सँधै कुनै पनि छनौट सुनिश्चित गर्न आवश्यक छ श्वासप्रश्वास यन्त्र, बाट ३M वा अर्को सम्मानित आपूर्तिकर्ता, साँच्चै हो NIOSH- अनुमोदित र विशिष्ट को लागी उपयुक्त खतरा। मेरो कम्पनी ZhongXing ले पनि प्राथमिकता दिन्छ उच्च गुणस्तर चिकित्सा-ग्रेड सामग्री र हाम्रा सबै उत्पादनहरूमा अनुपालन, हाम्रा ग्राहकहरूले हामीमा राखेको विश्वास बुझ्दै।

8. अधिकतम सुरक्षा: तपाईको श्वासप्रश्वास यन्त्रको प्रयोग र मर्मतका लागि उत्तम अभ्यासहरू के हुन्?

केवल एक प्रदान श्वासप्रश्वास यन्त्र पर्याप्त छैन; यसको प्रभावकारिता उचित प्रयोग र, को लागी निर्भर गर्दछ पुन: प्रयोज्य श्वसन यन्त्रहरू, मर्मतसम्भार। को लागी डिस्पोजेबल रेस्पिरेटरहरूजस्तै एक N95 रेस्पिरेटर, उचित प्रयोग को लागि सही आकार र मोडेल चयन संग सुरु हुन्छ लगाउने र सही फिट सुनिश्चित गर्दै। यसमा प्रायः फिट परीक्षण समावेश हुन्छ, जसलाई द्वारा अनिवार्य गरिएको छ OSHA धेरै कार्यस्थलहरूमा। द लगाउने कसरी सही ढंगले डन (अप) र डफ (टेक अफ) गर्ने बारे तालिम हुनुपर्छ श्वासप्रश्वास यन्त्र, र प्रत्येक पटक लगाउँदा प्रयोगकर्ता सिल जाँच कसरी गर्ने। द श्वासप्रश्वास यन्त्रका किनारहरू अनुहार संग पूर्ण सम्पर्क गर्नुपर्छ वरिपरि कडा छाप बनाउनुहोस् द नाक र मुख। सीलमा हस्तक्षेप गर्ने कुनै पनि अनुहारको कपालले सम्झौता गर्नेछ श्वासप्रश्वास यन्त्रको संरक्षण।

को लागी पुन: प्रयोज्य श्वसन यन्त्रहरू, मर्मत महत्वपूर्ण छ। यसमा नियमित निरीक्षण समावेश छ अनुहार, भल्भ, पट्टा, र क्षति वा पहिरन को लागी अन्य घटकहरु। कारतूस र फिल्टर ए अनुसार प्रतिस्थापन गर्नुपर्छ तालिका परिवर्तन गर्नुहोस् वा जब तिनीहरू फोहोर हुन्छन्, क्षतिग्रस्त हुन्छन्, वा सास फेर्न सकिन्छ सास फेर्न गाह्रो। सरसफाई र भण्डारण श्वासप्रश्वास यन्त्र निर्माताको निर्देशन अनुसार (3M सिफारिस गर्नुभयो तिनीहरूका उत्पादनहरूका लागि विशेष प्रक्रियाहरू) पनि महत्त्वपूर्ण छ। ए संग व्यवहार गर्ने कि डिस्पोजेबल श्वास यन्त्र वा पुन: प्रयोज्य, यो महत्त्वपूर्ण छ कि प्रयोगकर्ताहरूले तिनीहरूका सीमितताहरू बुझ्छन् सुरक्षा उपकरण। छैन श्वासप्रश्वास यन्त्र यदि यो क्षतिग्रस्त छ, फोहोर छ, वा सही तरिकाले लगाएको छैन भने सुरक्षा प्रदान गर्न सक्छ। रेस्पिरेटरहरू प्रदान गर्दछ यी सबै सर्तहरू पूरा भएपछि मात्र सुरक्षा।

9. कहिले अलविदा भन्न: तपाईंले आफ्नो डिस्पोजेबल रेस्पिरेटर वा यसको कार्ट्रिज/फिल्टर कति पटक बदल्नुपर्छ?

कहिले प्रतिस्थापन गर्ने थाहा छ डिस्पोजेबल श्वास यन्त्र वा कारतूस / फिल्टर एक पुन: प्रयोज्य मा एक को रखरखाव को लागी महत्वपूर्ण छ पर्याप्त सुरक्षा। को लागी डिस्पोजेबल फिल्टरिंग फेसपीस रेस्पिरेटरहरू, सामान्य जस्तै N95 रेस्पिरेटर, तिनीहरू सामान्यतया लागि अभिप्रेत छन् एकल प्रयोग वा एकल सिफ्ट भित्र विस्तारित प्रयोग, विशेष गरी स्वास्थ्य सेवा वा धुलो वातावरणमा जहाँ फिल्टर संग जोडिएको हुन सक्छ कण कुरा, बनाउने सास फेर्न गाह्रो, वा जब श्वासप्रश्वास यन्त्र माटो, क्षतिग्रस्त, वा सिल सम्झौता भएको छ। तिनीहरू हुनुपर्छ प्रयोग पछि खारेज कार्यस्थल नीति वा निर्माता सिफारिसहरू अनुसार। सफा वा पुन: प्रयोग गर्ने प्रयास गर्दै डिस्पोजेबल रेस्पिरेटरहरू तिनीहरूको अभिप्रेत जीवनकालभन्दा बाहिरले तिनीहरूको प्रभावकारितालाई उल्लेखनीय रूपमा कम गर्न सक्छ।

को लागी पुन: प्रयोज्य श्वसन यन्त्रहरू, द कारतूस र फिल्टर प्रतिस्थापन तालिका को प्रकार सहित धेरै कारक मा निर्भर गर्दछ दूषित, यसको एकाग्रता, सास फेर्ने दर लगाउने, तापक्रम, आर्द्रता, र निर्माता द्वारा प्रदान गरिएको सेवा जीवन सूचकहरू (यदि कुनै हो भने)। ग्यास र भाप कारतूस जस्तै दूषित पदार्थहरू अवशोषित गर्ने सीमित क्षमता छ जैविक वाष्पहरू वा एसिड ग्याँसहरू। एक पटक यो क्षमता पुगेपछि, "ब्रेकथ्रु" हुन सक्छ, यसको अर्थ दूषित मार्फत जान्छ कारतूस र द्वारा सास लिन्छ लगाउने। त्यसैले, एक सख्त तालिका परिवर्तन गर्नुहोस् वस्तुगत डेटा वा सेवा जीवन अनुमान उपकरणहरूमा आधारित (धेरै निर्माताहरू, सहित ३M, यी प्रदान गर्न आवश्यक छ)। कण फिल्टरहरू मा पुन: प्रयोज्य श्वसन यन्त्रहरू तिनीहरू फोहोर, क्षतिग्रस्त, वा श्वास प्रतिरोधमा उल्लेखनीय वृद्धि हुँदा प्रतिस्थापन गर्नुपर्छ।

10. मास्कभन्दा बाहिर: आत्म-निहित श्वास उपकरण (SCBA) कसरी फरक छ र यो कहिले आवश्यक छ?

जबकि सबैभन्दा सामान्य कार्यस्थल श्वसन सुरक्षा हावा शुद्धीकरण गरेर आवश्यकताहरू पूरा गर्न सकिन्छ श्वासप्रश्वासकहरू (जस्तै डिस्पोजेबल रेस्पिरेटरहरू वा तीसँग कारतूस र फिल्टर), त्यहाँ परिस्थितिहरू छन् जहाँ यी अपर्याप्त वा असुरक्षित छन्। यो जहाँ वातावरण आपूर्ति छ श्वासप्रश्वासकहरू, जस्तै a आत्म-निहित श्वास उपकरण (SCBA), खेलमा आउनुहोस्। ए SCBA सास फेर्ने सुविधा दिन्छ लगाउनेलाई हावा द्वारा लिइएको स्रोतबाट लगाउने- सामान्यतया एक संकुचित एयर सिलिन्डर। यसले यसलाई वायु-शुद्धीकरणबाट मौलिक रूपमा फरक बनाउँछ श्वासप्रश्वास यन्त्र, जसले परिवेशको हावा सफा गर्छ।

SCBA एकाइहरू जीवन वा स्वास्थ्य (IDLH) को लागि तुरुन्तै खतरनाक हुने वातावरणमा आवश्यक हुन्छन्, जस्तै:

- अक्सिजनको कमी भएको वायुमण्डल (१९.५% अक्सिजन भन्दा कम)।

- खतरनाक को धेरै उच्च सांद्रता ग्यास, भाप, वा कण जुन हावा शुद्धीकरणको क्षमताभन्दा बढी छ श्वासप्रश्वासकहरू वा तिनीहरूको एपीएफ.

- अज्ञात प्रदूषक वा अज्ञात एकाग्रता।

- धुवाँ, विषाक्त ग्याँस र अक्सिजनको कमी भएको ठाउँमा अग्नि नियन्त्रक कार्यहरू सामान्य छन्।

ए SCBA सामान्यतया a समावेश गर्दछ पूर्ण अनुहारको टुक्रा, कम्प्रेस्ड हावाको सिलिन्डर, हावाको चाप घटाउने रेगुलेटर, र हार्नेस। तिनीहरू सकारात्मक दबाबमा काम गर्छन् अनुहार दूषित हावाको भित्री चुहावट रोक्न। को उच्चतम स्तर प्रदान गर्दा श्वसन सुरक्षा, SCBA एकाइहरू भारी छन्, सीमित हावा आपूर्ति छ (सामान्यतया 30-60 मिनेट), र सुरक्षित प्रयोग र मर्मतका लागि व्यापक प्रशिक्षण चाहिन्छ। तिनीहरू एक महत्वपूर्ण टुक्रा हुन् सुरक्षा उपकरण आपतकालीन प्रतिक्रियाकर्ताहरू र अत्यधिक जोखिममा कामदारहरूको लागि पेशागत सेटिङहरू।

11. सोर्सिङ स्मार्ट: प्रोक्योरमेन्ट प्रबन्धकहरूले रेस्पिरेटर आपूर्तिकर्तामा के खोज्नुपर्छ?

मार्क थम्पसन जस्ता खरीद प्रबन्धकहरूको लागि, सोर्सिङ श्वासप्रश्वासकहरू- चाहे डिस्पोजेबल रेस्पिरेटरहरू जस्तै N95s वा पुन: प्रयोज्य श्वसन यन्त्रहरू विशिष्ट संग फिल्टरहरू र कारतूस- महत्वपूर्ण जिम्मेवारी संग एक कार्य हो। यो मूल्यको बारेमा मात्र होइन; यो सुनिश्चित गर्ने बारे हो सुरक्षा र स्वास्थ्य सम्भावित सयौं वा हजारौं व्यक्तिहरूको। आपूर्तिकर्ताहरूको मूल्याङ्कन गर्दा, विशेष गरी डिस्पोजेबल चिकित्सा उपभोग्य वस्तुहरू चीन जस्ता देशहरूबाट, धेरै कारकहरू सर्वोपरि छन्। पहिलो र प्रमुख छ NIOSH स्वीकृति (वा समतुल्य स्थानीय प्रमाणीकरण, जस्तै युरोपको लागि CE मार्किङ)। यो कसैको लागि गैर-वार्तालाप योग्य छ श्वासप्रश्वास यन्त्र लागि अभिप्रेरित कार्यस्थलमा व्यावसायिक प्रयोग। सँधै प्रमाणीकरणहरू प्रमाणित गर्नुहोस् र नक्कली उत्पादनहरूबाट सावधान रहनुहोस्।

प्रमाणीकरण भन्दा बाहिर, निर्माताको गुणस्तर व्यवस्थापन प्रणालीहरू विचार गर्नुहोस् (जस्तै, चिकित्सा उपकरणहरूको लागि ISO 13485)। तिनीहरूको आपूर्ति श्रृंखला र निर्माण प्रक्रियाहरूमा पारदर्शिता खोज्नुहोस्। एक कारखाना मालिकको रूपमा, म, एलेन, स्पष्ट संचार र जवाफदेहिता महत्त्वपूर्ण छ भनेर प्रमाणित गर्न सक्छु। मार्कको दुखाइ बिन्दुहरू, जस्तै असक्षम संचार र ढुवानी ढिलाइ, सक्रिय र भरपर्दो आपूर्तिकर्ताहरूसँग साझेदारी गरेर कम गर्न सकिन्छ। ब्याच ट्रेसिबिलिटी, शेल्फ लाइफ, र भण्डारण सिफारिसहरूको बारेमा सोध्नुहोस् श्वासप्रश्वासकहरू। जस्तै उत्पादनहरु को लागी 3M डिस्पोजेबल रेस्पिरेटरहरू, नक्कलीबाट बच्नको लागि तपाईंले अधिकृत वितरकहरूबाट खरिद गरिरहनुभएको छ भनी सुनिश्चित गर्नुहोस्। अन्ततः, को लागी एक राम्रो आपूर्तिकर्ता श्वासप्रश्वासकहरू र अन्य PPE गुणस्तर, अनुपालन, र ग्राहक समर्थनलाई प्राथमिकता दिनेछ, उनीहरूको उत्पादनहरू, हाम्रो जस्तै मेडिकल Bouffant क्याप्स वा नाक अक्सिजन क्यानुला, जीवन रक्षाको लागि महत्वपूर्ण छन्। तिनीहरूको बारेमा व्यापक प्राविधिक जानकारी प्रदान गर्न सक्षम हुनुपर्छ श्वासप्रश्वास यन्त्रको क्षमता, सीमितता र सही फिल्टर को प्रकार वा कारतूस बिरूद्ध सुरक्षा सहित विभिन्न खतराहरूको लागि जैविक वाष्पहरू, एसिड ग्याँसहरू, वा विभिन्न कण स्तरहरू।

याद गर्नका लागि मुख्य उपायहरू:

- खतरा पहिचान गर्नुहोस्: सधैं विशिष्ट मूल्याङ्कन गर्नुहोस् वायुजनित कणहरू, ग्यास, वा भाप ए चयन गर्नु अघि तपाईलाई सुरक्षा चाहिन्छ श्वासप्रश्वास यन्त्र.

- NIOSH स्वीकृति मामिलाहरू: कुनै पनि सुनिश्चित गर्नुहोस् श्वासप्रश्वास यन्त्र लागि प्रयोग गरिन्छ व्यावसायिक सुरक्षा र स्वास्थ्य छ NIOSH-अनुमोदित (वा बराबर स्थानीय मापदण्डहरू पूरा गर्दछ)। जस्तै चिन्हहरू खोज्नुहोस् N95, P100, आदि

- फिट महत्त्वपूर्ण छ: A श्वासप्रश्वास यन्त्र यदि यो बनाउँछ भने मात्र काम गर्दछ कडा छाप संग लगाउने को अनुहार। फिट परीक्षण अक्सर आवश्यक छ।

- फिल्टर र कारतूस बुझ्नुहोस्: सही छान्नुहोस् फिल्टर को लागी कण पदार्थ (तेल प्रतिरोधलाई विचार गर्दै) र दायाँ कारतूस विशिष्ट ग्यास वा वाष्पहरूको लागि।

- डिस्पोजेबल मतलब डिस्पोजेबल: डिस्पोजेबल रेस्पिरेटरहरू, धेरै जस्तै 3M डिस्पोजेबल रेस्पिरेटरहरू, सामान्यतया को लागी हो एकल प्रयोग वा सीमित प्रयोग। तिनीहरूको अभिप्रेत जीवन भन्दा बाहिर तिनीहरूलाई पुन: प्रयोग गर्ने प्रयास नगर्नुहोस्।

- परिवर्तन तालिका पालना गर्नुहोस्: को लागी पुन: प्रयोज्य श्वसन यन्त्रहरू, कडाई पालना गर्नुहोस् तालिका परिवर्तन गर्नुहोस् को लागी कारतूस र फिल्टर जारी सुनिश्चित गर्न पर्याप्त सुरक्षा.

- प्रशिक्षण आवश्यक छ: प्रयोगकर्ताहरूलाई उनीहरूको उचित चयन, प्रयोग, र सीमितताहरूमा प्रशिक्षित हुनुपर्छ श्वासप्रश्वास यन्त्र.

- चरम अवस्थाहरूको लागि SCBA: अक्सिजनको कमी वा IDLH वायुमण्डलका लागि, ए आत्म-निहित श्वास उपकरण (SCBA) आवश्यक छ।

सही छनौट र प्रयोग गर्नुहोस् श्वासप्रश्वास यन्त्र को एक महत्त्वपूर्ण घटक हो व्यक्तिगत सुरक्षा उपकरण रणनीति, व्यक्तिहरूको भीडबाट सुरक्षा गर्दै श्वासप्रश्वास खतराहरू।

पोस्ट समय: मे-०७-२०२५