I roto i te taiao-nui o te ruma whakahaere, he mea nui nga taputapu katoa. Engari he iti noa te hunga e arohaehae ana pera i te scalpel. He toronga o te ringa o te taote, te mata pokanga matau Ka taea te rereketanga i waenga i te ma, te whakaora tere kohanga me tetahi e puta ai he mamae kikokore. Mo te kaiwhakahaere hoko hōhipera pera i a Mark Thompson, he mahi tokena a pokapū hāparapara, ko te huinga o nga tau, o nga ahua, me nga taonga ka tino whakamataku. He aha te tino rereketanga o te #10 me te #15 mata? Ahea te waro maitai he pai ake te whiriwhiri kowiri tira? I te mea ko Allen, he kaihanga o nga taonga rongoa tuku noa i Haina, kua pau ahau i nga tau ki te tirotiro i te hanga o enei. taputapu faufaa. Tenei he aratohu ki te rahi o te mata poka ka huna te ao o te mata hāparapara, hei awhina i a koe ki te whakatau whakatau whakarite kei a koutou taote nga tika nga taputapu e tika ana kia tutuki i a raatau te pai nga hua o te manawanui.

He aha te Mata Haparapara me te aha te mea tino nui?

A mata hāparapara, ranei mata scalpel, he iti, tino koi taputapu tapahi e whakamahia ana mo te pokanga, te wehenga tinana, me etahi atu momo mahi rongoa. Kaore i rite ki te maripi paerewa, a mata hāparapara he mea hoahoa mo te kaupapa kotahi: ki te hanga ma, tapahi tika me te iti kino ki nga kopa a tawhio noa. Tenei tika ehara i te mea mo te rerehua anake; he mea tino nui ki te mahi whakaora. He ma kohanga hanga ki te koi scalpel ka tere ake te whakaora, ka iti ake te mate o te mate, ka iti ake te marumaru.

Ko enei he maha nga ahua me te rahi o nga matatahi, i hangaia ia mo te a mahi hāparapara motuhake. Ahakoa kei te mahia e te taote he kohanga nui i roto pokanga puku he tapahi ngawari ranei ki roto pokanga kirihou, te whakamahi i te mata pokanga tika he mea nui. Ko te whainga ko te tapahi kikokore ma te kore e pakaru, e haehae ranei nga pūtau, ka nui ake te urupare mumura me te roa o te whakaora. Koinei te take o te kounga, whakakoi, me te hoahoa o ia mata hāparapara he mea tino nui.

Te Wetewete i nga Tau: He aha te tikanga o nga rahi o te mata haparapara?

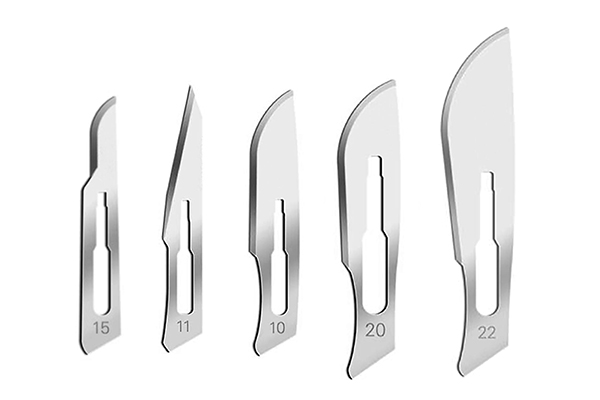

Ko te punaha tatau mo matatahi pokanga He ahua koretake i te tuatahi, engari he huarahi whai tikanga mo nga kairoro ki te tautuhi i te tika te rahi me te ahua o te mata e hiahia ana ratou. Ko te tikanga ka whakarōpūhia e te punaha matatahi i runga i te kakau e tika ana me te tikanga o te whakamahi.

Anei he wehenga taketake:

- Matatahi #10 ki te #19: Ko enei matatahi uru ki te #3 Te kirikiri Kakau. He iti ake, ka whakamahia mo nga tikanga ngawari ake ranei.

- Matatahi #20 ki te #25: Ko enei matatahi nui ake uru ki te #4 Te kirikiri Kakau a ko whakamahia pinepine mo te hanga nga waahanga nui ake i roto i te pokanga whanui, autopsy ranei.

Ko te tau o nga mata scalpel e tohu ana ki tona rahi me tona ahua. Hei tauira, he #10 mata me te #15 mata ka uru nga mea e rua ki te kakau #3, engari he tino rereke nga ahua ka whakamahia mo nga momo tapahi rereke. Ko te maarama ki tenei punaha te mahi tuatahi te kōwhiri i te mata hāparapara tika.

He Tirohanga Hohonutanga ki nga Momo Matatahi Hangaia

Ahakoa tatini o momo mata kei te noho tonu, he maha nga rahinga matua i roto i nga mea katoa ruma whakahaere. Ko te mohio ki o raatau ahuatanga he mea nui mo tetahi kaiwhakahaere rongoa.

| Tau Mata | Whakaahuatanga | Whakamahinga noa |

|---|---|---|

| #10 Mata | A mata kōpiko me te mata tapahi nui. Koia tetahi o nga ahua mata mata. | Ka whakamahia mo te hanga tapahi nui i roto i te kiri me te uaua, penei i roto i te whanui me te pokanga orthopedic. |

| #11 Mata | He tapatoru mata me te pito koi, tohu. Kei te mohiotia ano he "tuu" mata. | Ka whakamahia mo te hanga he tika, he poto nga tapahi, penei i te whakaheke i te kopu, te whakauru ranei i te ngongo pouaka. |

| #15 Mata | He iti mata kōpiko me te mata tapahi iti ake, he rite ki te iti #10 mata. | Ka whakamahia te tikanga mo te hanga nga waahi iti, nga tapahi uaua, i roto ranei i nga tamariki, i nga mahi kirihou ranei. |

| #20 Mata | He putanga nui ake o te #10 mata, e whakaatu ana i tetahi rongonui kopikopiko mata tapahi. | Ka whakamahia mo nga waahanga nui ake i roto i nga tukanga penei i te thoracic ranei pokanga puku. Ka uru ki te kakau #4. |

E wha enei matatahi kapi i te whānuitanga nui o hāparapara nga hiahia, mai i te whanui, nga tapahi tapatapahi tae noa ki nga weronga ngawari.

Me pehea e whiriwhiri ai koe i te Mata Matau mo te Mokohanga Haangai Motuhake?

Te whiriwhiri i te mata pokanga tika ka whakawhirinaki katoa ki te mahi kei a koe. Ko te whiringa ka whakatauhia e te momo kohanga e hiahiatia ana ka tapahia te kiko. Ka whakaarohia e te taote he maha nga mea whiriwhiria te tika taputapu mo te teitei tika me te haumaru.

- Mo nga tapahi roa, tika: He nui, mata kōpiko rite te #10 mata ranei #20 mata he pai. Ko te kopikopiko o nga mata ka taea e te taote te whakamahi i te kopu o te mata ki te hanga i te tapahi maeneene, haere tonu me te nekehanga kotahi. He pai ake tenei, he iti ake te hua kino te kiko atu i te mahi tapahi iti maha.

- Mo nga tapahi poto, tika: Ina hiahiatia nga mahi uaua, penei i te ophthalmology, dermatology ranei, a #15 mata Ko te nuinga o nga wa ko te taputapu whiriwhiri. Ko tana rahi iti ka taea te whakahaere me te kaha ki te whakahaere.

- Mo nga werohanga werohanga: Te tohu koi #11 mata he mea hanga motuhake mo tenei kaupapa. Ko tona ahua tapatoru he tino pai mo te wero i te kiko ki te whakaheke i te kohinga wai, ki te whakatuwhera ranei i te tuwhera mo te whakauru i te ngongo, i te wairere ranei.

Ko te whakangungu me te wheako o te taote he mea nui, engari ko te whai taputapu tika ko te watea he tikanga mo te angitu. Kei roto i tenei ehara i te mea ko te mata, engari ano hoki nga mea e pa ana penei tui parakore ki te ngira ki te kati i te kohanga muri iho.

Carbon Steel vs. Kowiri tira: Te whiriwhiri i te Rauemi Mata Matau

Ko te rauemi o te mata he take tino nui e whakaawe ana i ana mahi, ina koa ko tana mahi te koi me te mauroa. Ko nga rauemi e rua e tino whakamahia ana mo te tuku matatahi pokanga he waro maitai a kowiri tira. Hei kaihanga, ka whakaputahia e matou nga mea e rua, na te mea he pai nga painga o ia tangata.

Matatahi waro maitai He rongonui mo o raatau tuatahi whakakoi. Ko te hanganga witi pai o waro maitai ka taea te whakakoi ki te mata tino pai, he koi koi atu kowiri tira. He maha nga wa ka pai nga kaitoro waro maitai mo nga tukanga e tino pai ana tika e hiahiatia ana mo te tuatahi kohanga. Heoi, waro maitai he pakarukaru ake, he whakaraerae ki te waikura me te waikura, no reira me pakari tona putunga hei tiaki i te makuku.

Matatahi kowiri tira, i tetahi atu ringa, he tino atete ki waikura. Ma tenei ka kaha ake te roa, ka roa ake te ora o te papa. Ahakoa pea he hautau iti ake te koi i te timatanga waro maitai, kounga teitei matatahi kowiri tira kia mau tonu to ratou mata puta noa i te tukanga. Ko to ratou atete ki te waikura ko te tikanga karekau he tupono ka mahue nga matūriki whakarewa i roto i te kohanga. I te nuinga o te wa ka tae mai te whiringa ki runga i te manakohanga pokanga me nga whakaritenga motuhake o te hāparapara.

He aha te mea he mea nui te Kakau Matau Matau?

A mata scalpel he horihori ki te kore he kakau hei pupuri. Ko te kakau mata, e mohiotia ana ano ko te kakau Bard-Parker, he taputapu ka taea te whakamahi ano e te tuku mata piri ki. Ka rite ki he maha nga rahi o nga matatahi, pera ano nga kakau. Ko te matua ko te hototahi.

- #3 Kakau: He iti ake enei, he mea hoahoa ki te pupuri matatahi i roto i te raupapa #10-#19. Ka whakamahia mo nga mahi ngawari ake.

- #4 Kakau: He nui ake, he pakari ake enei, i hangaia hei pupuri i te rahi ake matatahi o te raupapa #20.

He mea tino nui ki kia rite ki te rahi o te mata ki te kakau tika. E ngana ana ki te uru ki te #15 mata ki runga i te kakau #4 e kore e mahi, e noho haumaru ana. I te wa e tokena ana he ruma whakahaere, he mea nui ki te whai rawaka o nga momo kakau e rua hei whakauru i nga mea rereke katoa momo mata whakarato koe. Ko te taumaha o te kakau, te toenga, me te hopu ergonomic ka whai waahi ano ki te mana whakahaere a te taote me te whakaiti i te ngenge i roto i nga mahi roa.

He pehea te Paanga o te Hanga o te Mata ki tetahi Tikanga Hapara?

Ko te te ahua o te mata ehara i te mea noa; ia kopikopiko me te tohu he mea hoahoa mo a hāparapara motuhake mahi. Ko te hoahoa mata ka tohu me pehea te neke i roto i te kiko me te momo tapahi ka puta. A mata tika, hei tauira, he pai mo nga tapahi pana, ko te a mata kōpiko he pai ake mo te tapahi.

Ko te kopikopiko runga a #10 mata taea mo te roa, tahia kohanga ka tohatohahia te pehanga ki te taha tapahi. Ma tenei ka pai ake te tapahi i te tapa tika, ka keri ki te pito. Ko te pito tohu o te #11 mata ka whakakorikori i te kaha katoa ki te waahi kotahi, kia ngawari te kuhu me te iti o te kaha. Tenei momo i roto i te rahi me te ahua o te mata ka hoatu e nga kairoro he kete taputapu maha, ka taea e ratou te kowhiri i te taputapu tino pai whakarite te mahi ma o ia pokanga taahiraa, mai i te timatanga kohanga ki te whakakorenga whakamutunga.

Mai i te Tirohanga a te Kaihanga: Me pehea te Whakapumau i te Koi o te Mata?

Ka rite ki te kaiwhakanao, whakapūmau i te kounga me te whakakoi o to tatou matatahi pokanga ko ta matou kaupapa matua. Ko te tukanga he huinga o te whakamahi i nga rawa pai ake me te whakamahi i nga tikanga whakangao matatau. Ka timata ma te rapu i nga taumata teitei waro maitai ranei kowiri tira mai i nga kaiwhakarato whakawhirinaki.

Ko te mea tino nui ko te mahi huri me te whakakoi. Ka whakamahia e matou nga miihini miihini, rorohiko-rorohiko hei hanga i te mata tapahi i te koki tika. Ka aroturukihia tenei tukanga i ia wahanga ki te whakarite riterite. I muri i te huri, ia mata ka whai i te tukanga whakaoti whakamutunga ki te tango i nga pupuhi moroiti, ka puta he mata tino maeneene, koi heu. Ko nga arowhai mana kounga, tae atu ki te tirotiro miihini me te whakamatautau koi, ka mahia ki runga i nga tauira mai i ia puranga. Ko tenei piripono ki te kounga ka pehea tatou whakarite e to tatou ka mau tonu nga matatahi koi, me te pono, i roto i te tahuri ka whakanui i te manawanui te haumaru me te tautoko i nga huanga pokanga pai. Koinei nga korero e pa ana ki te whiriwhiri i nga momo rereke taonga rongoa.

He Rauemi etahi atu me nga momo matatahi e whakamahia ana i roto i te pokanga?

Ahakoa waro maitai a kowiri tira te nuinga o te maakete mo te tuku matatahi, motuhake taputapu hāparapara he mea hanga mai i etahi atu rauemi. He utu nui ake enei ka rahuitia mo nga mara tino motuhake.

- Mata Uira: Hangaia nga matatahi mai i te uku he tino uaua ka taea te pupuri i te mata mo te wa roa. He kore-aukume ano hoki, he mea whai hua i roto i nga tukanga e pa ana ki te MRI.

- Mata Taimana: I whakamahia tata anake ki te ophthalmology, taimana matatahi Ko nga taputapu tapahi koi rawa atu e waatea ana, e kaha ana ki te hanga tapahi tino tika i roto i nga kopa ngawari o te kanohi.

- Matapihi Ka taea te whakamahi ano: Ahakoa te mea hou matatahi pokanga he mea whakamahi kotahi hei aukati i te paheketanga, etahi motuhake, mahi taumaha matatahi kua hoahoatia kia noho matatahi ka taea te whakamahi ano i muri i te whakahoromatatanga.

Mo te nuinga o nga tukanga, heoi, ko te whiriwhiri i waenga waro a matatahi kowiri tira whakarato i te mahi e tika ana, me te ko te otinga tino-utu whai hua mo te hōhipera pukumahi ranei pokapū hāparapara.

Nga Whakaaro Matua Ina Whiriwhiria te Kaiwhakarato Mata Matau

Mo te kaiwhakahaere hoko, te kōwhiri i te mata hāparapara tika ka toro atu ki te whiriwhiri i te kaiwhakarato tika. Ko to whakatau kaore e pa ana ki to tahua anake engari ki te kounga o te tiaki e whakaratohia ana e to whare.

- Kounga me te Tautukunga: Whakaritea ka piri te kaiwhakarato ki nga paerewa kounga o te ao penei i te ISO 13485 me nga whakaaetanga ture e tika ana (hei tauira, te tohu CE, te whakamana FDA) mo to maakete.

- Puata Rawa: Me marama te kaiwhakarato mo te reanga o waro maitai ranei kowiri tira whakamahia. Ka pa tika tenei ki te te mata mahi.

- Tauritenga: Ko te whakakoi me te kounga o te matatahi me rite tonu mai i tetahi puranga ki tetahi atu. Patai mo o raatau tikanga whakahaere kounga.

- Tikanga Taapapa: Matatahi me takai marie ki roto i nga paatete ngawari ki te tuwhera, parakore hei tiaki i a raatau mai i te kino me te kino waikura.

- Raina Whakawhiwhi Whakapono: Me kaha to kaiwhakarato ki te tuku i o ota i runga i te waa kia kore ai e ngaro enei mea nui taputapu hāparapara, rite matatahi ranei ngongo hono ngongo.

Ko te mahi tahi me tetahi kaihanga mohio e mohio ana ki enei whakaritenga he mea nui ki te pupuri i a koe ruma whakahaere he pai nga taonga me te pono, te mahi nui matatahi pokanga.

Nga Taketake matua

- He mea nui te nama: Ko te tau runga a mata hāparapara e tohu ana i tona rahi me te ahua. Matatahi #10-#19 ka uru ki te kakau #3, ko te #20-#25 ka uru ki te kakau #4.

- Whakaōritea te Mata ki te Mokowhiti: Whakamahia nui, mata kōpiko (#10, #20) mo nga tapahi roa me te iti, motuhake matatahi (#11, #15) mo nga tapahi tika, werohia ranei.

- Ko te Kowhiringa Rawa te mea matua: Matatahi waro maitai tuku tuatahi pai whakakoi, i te wa matatahi kowiri tira whakarato i te mauroa pai me te waikura ātete.

- Precision Aukati i te Trauma: Te whakamahi i te mata tika ka puta he tapahi ma, ka tere ake te whakaora, ka iti te marumaru, ka iti ake te mate o te mate.

- Ko te kounga kaore e taea te whiriwhiri: Ko te whakakoi, riterite, me te whakakorikori o a mata hāparapara he mea tino nui mo te haumaru o nga turoro.

- Whiriwhiria to Kaihoko Ma te Maamaa: Mahi tahi me tetahi kaihanga ka taea e ia te whakarato i te kounga teitei, e tika ana matatahi pokanga me te whakaatu i te mekameka tuku pono me te marama.

Te wa tuku: Oketopa-29-2025